E-Commerce Fulfillment Automation

Enhance your competitive advantage and meet customer demand, quickly

Customers today expect companies to provide a fast and seamless eCommerce shopping experience. Providing a quick turnaround time, fast shipping, and accurate order fulfillment are critical to meeting these expectations. Luckily, eCommerce fulfillment automation makes that possible.

What is Automated Fulfillment?

Automated fulfillment refers to the use of technology-driven systems and processes to streamline and optimize the order fulfillment process in warehouses or distribution centers. This automation aims to improve efficiency, accuracy, and speed while reducing labor costs and errors.

Some of the key technologies involved in automated fulfillment include:

Warehouse Management Systems (WMS)

These are software platforms that manage and control warehouse operations, including inventory management, order processing, and picking optimization.

Pick-to-Light and Put-to-Light Systems

These systems use light indicators to guide warehouse workers through the picking and packing process, reducing errors, and increasing productivity. You can read more about these systems here!

Automated Storage and Retrieval Systems (ASRS)

ASRS are systems that use robots or automated mechanisms, like AutoStore, to store and retrieve items from shelves or racks, typically in a high-density configuration. This technology helps maximize storage space and improve picking efficiency.

Sortation Systems

Automated sortation systems use conveyor belts, diverters, and other mechanisms to sort and route items to the appropriate shipping lanes or packing stations based on destination, order type, or other criteria.

By integrating these technologies and processes, automated fulfillment systems can significantly increase the speed and accuracy of order processing, reduce labor costs, and enhance customer satisfaction through faster and more reliable delivery times.

Here’s how e-Commerce fulfillment automation helps:

Accuracy

Eliminate inventory errors with automated sorting, picking, packing, and retrieving.

Speed

Shorten eCommerce turnaround times by improving the efficiency of order fulfillment.

Scale

Flexibly adapt your warehouse productivity to meet fluctuating customer demands.

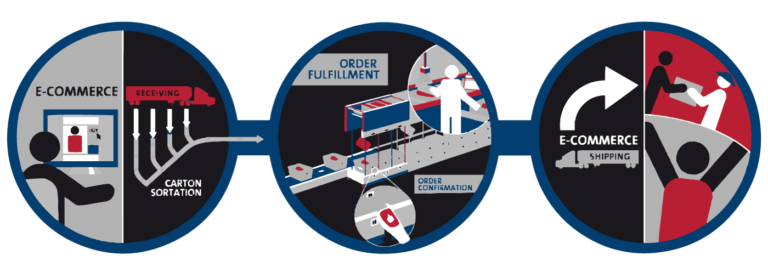

Automating the e-Commerce Fulfillment Workflow

Automating your eCommerce fulfillment workflow ensures that your customers never have to deal with delays in turnaround time, inaccurate orders, or slow shipping from manual fulfillment methods. That’s because our automation solutions are with you every step of the way.

Receiving Inventory Shipments

With several sortation automation solutions, sorting inventory can be customized to the exact needs of your warehouse. For instance, you can choose from the following automated sortation solutions:

Inventory Storage

AutoStore, our Automated Storage and Retrieval System (ASRS), helps you save up to 80% of your available floor space with 4X the storage capacity. With AutoStore, your eCommerce inventory is stored in bins designed to stack together in columns controlled by robots. These robots are small carts with wheels that glide across a compact aluminum grid. And the configuration of this system can be customized to any facility layout to maximize inventory storage.

eCommerce Order Processing

AutoStore also helps improve the efficiency of your eCommerce order processing to ensure that your supply chain is ready to scale with your customers’ demands. AutoStore robots are designed with an elevator-type mechanism that retrieves the correct bins for an order, and transports these bins to a port where the person at the port is presented with each bin and told precisely which items to take out.

Benefits of Automated Order Processing

1. Enhanced Efficiency

Automation streamlines the order processing workflow, reducing manual intervention, and optimizing processes. Orders can be fulfilled faster and more accurately, leading to quicker turnaround times and improved customer satisfaction.

2. Reduced Errors

e-Commerce Fulfillment solutions work to minimize the potential for human error through automated order fulfillment processes. By leveraging technologies such as barcode scanning, RFID tracking, and automated picking systems, the likelihood of mistakes in order accuracy and inventory management is significantly reduced.

3. Cost Savings

Automated order fulfillment processing helps reduce labor costs associated with manual order fulfillment tasks. With fewer labor hours required for repetitive tasks like picking, sorting, and packing, businesses can reallocate resources to higher-value activities or scale operations without proportionally increasing labor expenses.

4. Scalability

Automated systems can scale more easily to accommodate fluctuations in order volume or business growth. Whether your business is handling a few orders per day or thousands, automated fulfillment processes can adjust accordingly, ensuring consistent performance and minimizing the need for additional infrastructure or manpower.

Shipping

With full order consolidation at each port, eCommerce orders are ready for shipping in faster timeframes, with fewer inventory errors. This means that your customers can receive their orders in the turnaround times they expect, offering a positive overall shopping experience.

Returns Processing

If customers aren’t satisfied with a product, you can automatically process and sort the return or exchanges. Likewise, the correct bins for storage can be transported to the port automatically for the item to be exchanged or stored properly in the warehouse. This process can be customized to reflect your unique business policies.

eCommerce Industry Challenges

While the eCommerce industry has lots of benefits, there are also significant challenges that threaten to hold companies back. Notably, the eCommerce industry is driven by customer demand via technology. Likewise, in order to be successful, supply chain management and fulfillment must match the technological innovations fueling this demand. Manual order fulfillment is simply not able to match online demand, resulting in the following challenges:

- Expedited turnaround time and delivery requests

- Inventory sorting, picking, packing, and retrieving issues

- Varying and seasonal customer demand

- A high volume of product SKUs

- High competition in the eCommerce marketplace

eCommerce Fulfillment Considerations

When evaluating eCommerce fulfillment solutions, it’s important to consider the following aspects:

- Pain points in your current customer experience

- The size of your inventory and potential new product development

- Warehouse storage needs

- Shipping locations

- Software capabilities

- Future growth and scalability

Automated eCommerce Fulfillment Solutions

Frequently Asked Questions

In the eCommerce industry, fulfillment is the process of sorting, storing, retrieving, packing, and shipping orders, as well as managing product returns or exchanges.

eCommerce fulfillment automation is a new method of fulfillment that uses technology to sort products, store inventory, retrieve items, and pack and ship eCommerce orders. Automating the time-consuming fulfillment workflow reduces inventory errors, saves time, and improves turnaround times.

eCommerce Order Fulfillment is automated with the help of sortation equipment and an Automated Storage and Retrieval Solution such as AutoStore. Together, these solutions automate every step of the fulfillment process and streamline eCommerce operations.

eCommerce is a notoriously difficult and competitive industry, and automation is important because it makes it possible for companies to overcome these challenges. With improved order accuracy, eCommerce turnaround times, and scalability, companies are empowered to provide a positive customer experience and establish a competitive advantage.

Automated fulfillment significantly enhances order processing speed through the implementation of advanced technologies and streamlined processes. By automating tasks such as order picking, sorting, and packaging, manual labor is reduced, and the entire fulfillment workflow is optimized for efficiency.

Additionally, real-time data integration and analytics provide instant visibility into inventory levels, order statuses, and performance metrics, enabling swift decision-making and proactive problem-solving.

Automating fulfillment processes yields substantial cost benefits for businesses. By reducing reliance on manual labor, automated systems lower labor costs while simultaneously increasing efficiency and throughput. Moreover, automation minimizes errors in order processing, leading to fewer returns, replacements, and associated expenses. With optimized inventory management facilitated by automation, businesses can reduce carrying costs and avoid overstocking or stockouts, further optimizing operational expenses.

YES!

Small e-Commerce businesses can benefit from automated fulfillment solutions. While automation is traditionally associated with larger facilities, advancements of the technology partnered with the scalability of automation solutions has made room for automated solutions in the small e-Commerce field.

Additionally, we see the same benefits that larger companies experience- an increase in efficiency, accuracy, scalability, and a unique competitive advantage by having even faster order processing times.

Inventory management integrates seamlessly with automated fulfillment by leveraging technology to optimize inventory levels, streamline order processing, and ensure accurate order fulfillment. The automated systems we’ve mentioned, like ASRS and RFID scanning, provide instant visibility into stock levels and locations within the warehouse. This information is then used to automate order picking, replenishment, and allocation processes, ensuring that orders are fulfilled promptly and accurately.

By synchronizing inventory management with automated fulfillment, businesses can minimize stockouts, reduce excess inventory holding costs, and maintain optimal inventory levels to meet customer demand efficiently.

Secure Your Competitive Edge with AutoStore

THE WORLD’S FIRST AND LARGEST AUTOSTORE DISTRIBUTOR