AutoStore

Goods to person fulfillment

Strengthen supply chains with warehouse automation

Satisfying your customers’ demands has never been more challenging, but

AutoStore makes it easy.

Powered by robots, our Automated Storage and Retrieval System (ASRS) ensures that your supply chain is always ready to scale with your customers’ demands.

This solution does not require light in the aisles, or aisles for that matter, as there are no people picking. The savings due to energy and space can vary but are overall high in comparison to other solutions.

IMPROVE ROI

Increase your productivity by picking and packing more orders per hour while reducing inventory errors.

SAVE TIME

Improve your efficiency and shorten the delivery time for customers’ orders.

REDUCE STORAGE FOOTPRINT

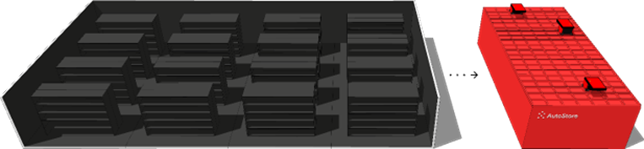

Save up to 80% of your available floor space with 4X the storage capacity.

Features of the AutoStore ASRS System

The autostore bin capacity system stands out with a maximum load of 30 kg (66 lbs), ensuring secure storage. It accommodates various bin layer configurations, with options ranging from 24 layers for 220 mm bins, 16 layers for 330 mm bins, to 14 layers for 425 mm bins. This adaptable approach to layering emphasizes the system’s versatility. Products find their place within stacked bins, forming a grid-based, high-density storage solution.

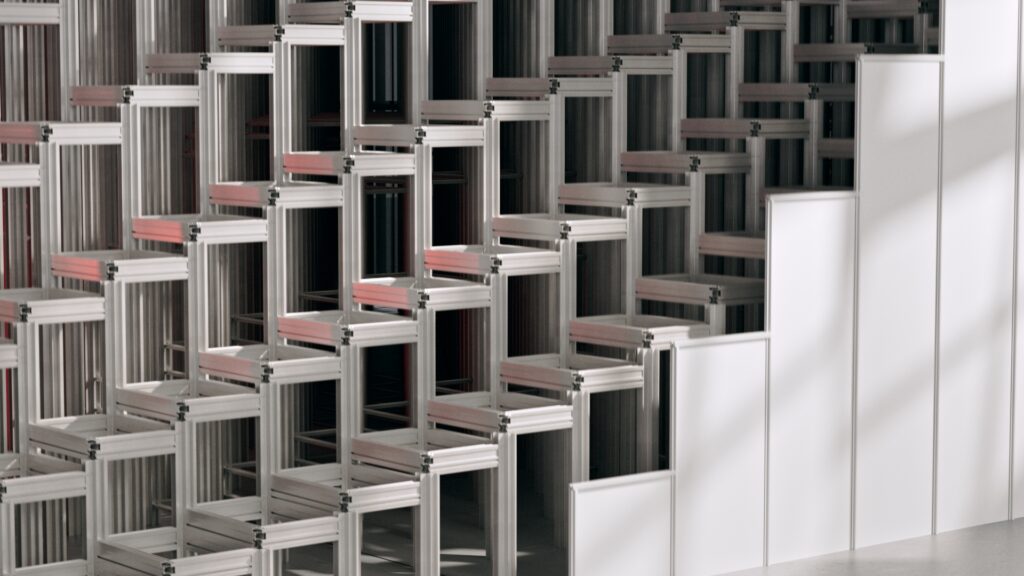

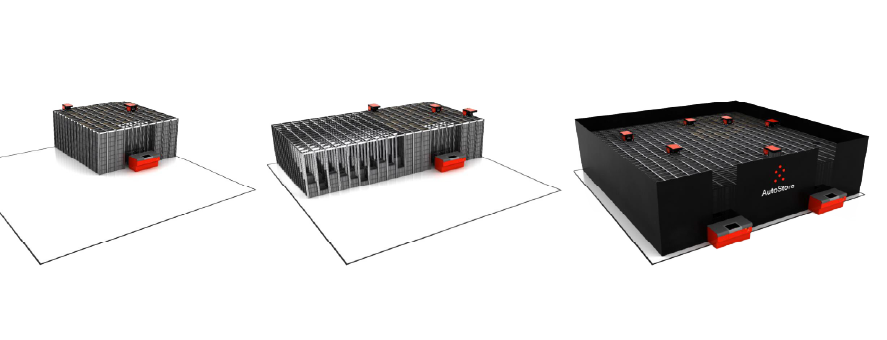

The aluminum grid provides storage space for the bins & tracks for the robots to drive on. Made of only 17 unique parts, it is modular & flexible, making it easy to install & fit to any floorplan.

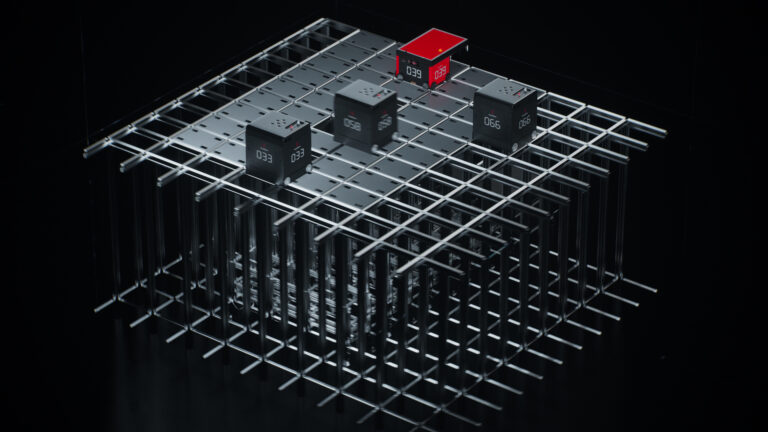

Robots travel along the top of the grid, retrieving Bins & delivering them to Ports, or workstations. Robots are able to access any bin & deliver to any Port in the system.

The aluminum grid provides storage space for the bins & tracks for the robots to drive on. Made of only 17 unique parts, it is modular & flexible, making it easy to install & fit to any floorplan.

The aluminum grid provides storage space for the bins & tracks for the robots to drive on. Made of only 17 unique parts, it is modular & flexible, making it easy to install & fit to any floorplan.

Advantages of the AutoStore ASRS System

- No Aisles Needed

- No Shelving Requirements

- Natural Slotting

Fast moving Bins always reside at the top; slotting performed automatically. - System Flexibility

Great for lower ceiling height facilities as well as tall; can fit any facility layout/shape.

- No Single Point of Failure

Fully redundant system. - Pick and Replenish in Parallel

No need to interrupt activities.

- Future Proof

Size and purchase for current needs and expand as required. System extensions able to be done without shutting down current operations

- Green Solution

Battery powered Robots consume 60% less energy compared to other technologies

AutoStore FAQs

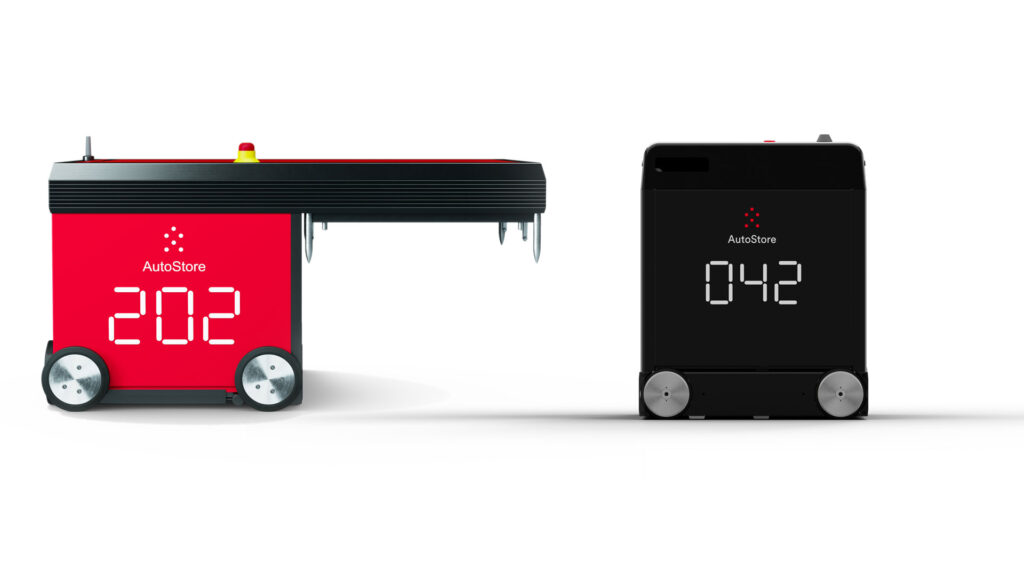

AutoStore robots are small carts with wheels that automate the storage and retrieval of inventory. The robots glide across the top of an aluminum grid and have an elevator-type mechanism that is able to identify, retrieve, and transport inventory orders within a facility.

An AutoStore ASRS system stores inventory in bins that stack on top of one another creating columns. The inventory within these bins is moved by robots. These robots are small carts with wheels that glide across the top of the aluminum grid and have an elevator-type mechanism that digs out the necessary bins. The robots take the bins needed to create the orders and bring them to a port. The person at the port is presented with one bin at a time and told which item(s) to take out to complete the order.

AutoStore systems are often used for automated order picking and inventory preparation in distribution centers. They can also be used in the following industries:

- eCommerce

- Retail

- Electronics

- Healthcare

- Pharmaceutical

- And more!

Using an AutoStore system helps resolve numerous challenges in picking, inventory, and supply chain management. This includes the following challenges:

- Limited warehouse space

- Oddly shaped facilities

- A high volume of SKUs

- Fluctuating demand for orders

- Split case items

Secure Your Competitive Edge with AutoStore

THE WORLD’S FIRST AND LARGEST AUTOSTORE DISTRIBUTOR