Warehouse compliance is a critical cornerstone for ensuring the seamless functioning of operations while adhering to established regulations and prioritizing the safety of workers. Maintaining compliance within a warehouse environment is not merely a legal obligation but a strategic imperative for businesses.

By adhering to industry standards and regulations, organizations can mitigate risks, enhance efficiency, and build a foundation for sustainable growth. Warehouse compliance encompasses a range of factors, including proper storage, handling of goods, and the implementation of safety protocols. It serves as a safeguard against potential legal repercussions, financial losses, and, most importantly, ensures the well-being of the workforce. In this context, warehouse compliance emerges as an integral element in the pursuit of a productive and secure operational environment.

What is compliance in a warehouse?

Warehouse compliance, as briefly touched upon above, refers to the adherence to established rules, regulations, and standards governing the storage, handling, and distribution of goods. This includes but is not limited to compliance with safety guidelines, industry-specific regulations, and legal requirements related to the warehouse’s operations.

Warehouse compliance ensures that the facility operates within the bounds of the law and industry best practices, promoting a safe working environment, preventing potential hazards, and maintaining the integrity of stored goods. It involves meticulous attention to details such as inventory management, equipment maintenance, and employee training to meet the prescribed standards, ultimately contributing to the efficiency, safety, and legality of warehouse operations.

Examples of standard warehouse compliance

- OSHA Regulations (Occupational Safety and Health Administration): OSHA sets forth guidelines to maintain a safe and healthy workplace. In a warehouse, this includes proper training for handling equipment, such as forklifts, and ensuring the availability of safety gear. Regular inspections and protocols to address potential hazards are also essential for compliance.

- Environmental Regulations: Warehouses must adhere to environmental regulations to minimize their ecological impact. This involves proper waste disposal, handling of hazardous materials, and implementing practices that reduce energy consumption. Compliance with environmental standards contributes to sustainability and corporate responsibility.

- FDA Regulations (Food and Drug Administration): Warehouses dealing with pharmaceuticals, medical devices, or food products need to comply with FDA regulations. This includes maintaining proper storage conditions, tracking batch numbers, and ensuring the integrity of products from receipt to distribution to meet stringent quality and safety standards.

- ISO 9001 (Quality Management Standards): Adhering to ISO 9001 standards demonstrates a commitment to quality management. Warehouses following ISO 9001 ensure rigorous quality control measures, systematic documentation of processes, and continuous improvement, which enhances overall efficiency and customer satisfaction.

- Customs and Trade Regulations: Warehouses involved in international trade must comply with customs regulations. This involves accurate record-keeping, adherence to import/export regulations, and compliance with customs duties. Non-compliance can lead to delays, fines, or even legal action.

Benefits of warehouse compliance

Warehouse compliance yields a myriad of benefits crucial for the sustained success of operations. Firstly, strict adherence to regulations helps in avoiding legal issues and potential fines. By aligning with OSHA, FDA, customs, and other applicable standards, warehouses mitigate the risk of violating laws, safeguarding the business from legal consequences.

By following compliance initiatives, you can significantly contribute to improving safety within the warehouse environment. Rigorous adherence to safety protocols and proper training not only protects the well-being of workers but also reduces the likelihood of workplace accidents and injuries.

Additionally, warehouse compliance plays a pivotal role in enhancing operational efficiency. By following quality management standards like ISO 9001, warehouses can optimize processes, reduce errors, and streamline workflows, leading to increased productivity and cost-effectiveness.

Lastly, maintaining compliance positively impacts the reputation of the warehouse. Demonstrating a commitment to regulatory standards and ethical business practices builds trust among stakeholders, including customers, suppliers, and regulatory authorities. This enhanced reputation not only attracts business partners but also positions the warehouse as a responsible and reliable player in the market, contributing to long-term success.

Warehouse compliance tips

- Implement a Compliance Program:

- Develop written procedures outlining compliance requirements for various aspects of warehouse operations.

- Integrate compliance training into the onboarding process for new warehouse workers, ensuring they understand and follow established protocols.

- Conduct regular audits and inspections to assess compliance levels, identify areas for improvement, and address any potential issues promptly.

- Ensure Safety Compliance:

- Prioritize fire safety by implementing and regularly testing fire prevention measures, ensuring the availability and functionality of firefighting equipment, and conducting fire drills.

- Establish protocols for handling hazardous materials safely, including proper storage, labeling, and emergency response procedures.

- Regularly maintain and inspect equipment such as forklifts, conveyor belts, and other machinery to prevent accidents and ensure compliance with safety standards.

- Inventory Management Best Practices:

- Implement stock rotation procedures to ensure older stock is used or sold first, reducing the risk of product obsolescence.

- Utilize advanced inventory tracking systems to monitor stock levels, track product movements, and facilitate accurate order fulfillment.

- Follow the FIFO (First In, First Out) method to minimize the risk of product spoilage or expiration, especially in industries dealing with perishable goods.

- Employee Training:

- Establish ongoing training programs that cover both compliance requirements and evolving industry best practices. This ensures that employees stay updated on the latest regulations and safety procedures.

- Ensure that relevant employees acquire any necessary warehouse safety certifications, such as for operating specific equipment or handling hazardous materials.

- Documentation:

- Emphasize the importance of proper documentation and record-keeping to capture essential information related to compliance.

- Document training sessions, safety drills, and any incidents, maintaining a comprehensive record that can be referenced during audits or in case of legal inquiries.

By incorporating these warehouse compliance tips into daily operations, businesses can create a culture of safety, efficiency, and adherence to regulations, ultimately promoting the success and sustainability of their warehouse operations.

How technology can help with warehouse compliance

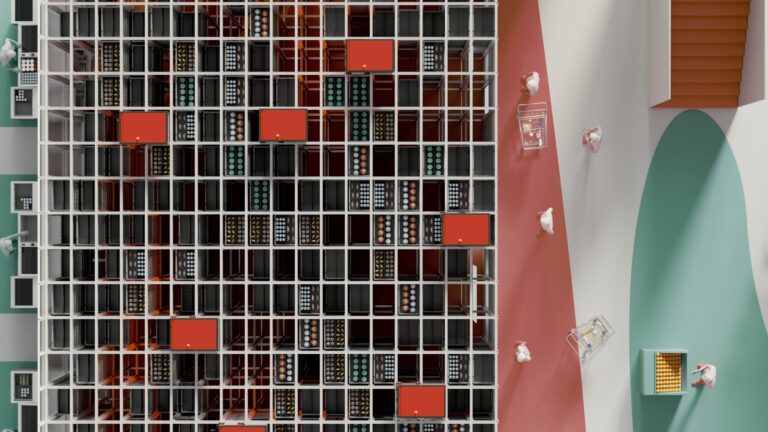

The integration of technology in warehouse operations has revolutionized the landscape of compliance, offering sophisticated solutions that not only enhance efficiency but also ensure adherence to regulatory standards. Warehouse Management Systems (WMS) and Inventory Management Systems have emerged as essential tools in this regard. These systems provide real-time visibility into inventory levels, order statuses, and movement patterns. By automating and optimizing various warehouse processes, WMS and inventory management systems contribute to accuracy in stock management, reducing errors and promoting compliance with inventory control regulations. Furthermore, they streamline order fulfillment processes, ensuring timely and accurate shipments, which is critical for compliance in various industries.

Temperature and humidity monitoring technology has become indispensable, especially for warehouses dealing with sensitive goods such as pharmaceuticals, food, and electronics. Automated sensors continuously track environmental conditions, sending immediate alerts if parameters deviate from preset standards. This not only helps in preventing damage to goods but also ensures compliance with regulatory requirements for proper storage conditions. The ability to provide a detailed history of temperature and humidity levels is crucial during audits, demonstrating the warehouse’s commitment to maintaining optimal storage conditions.

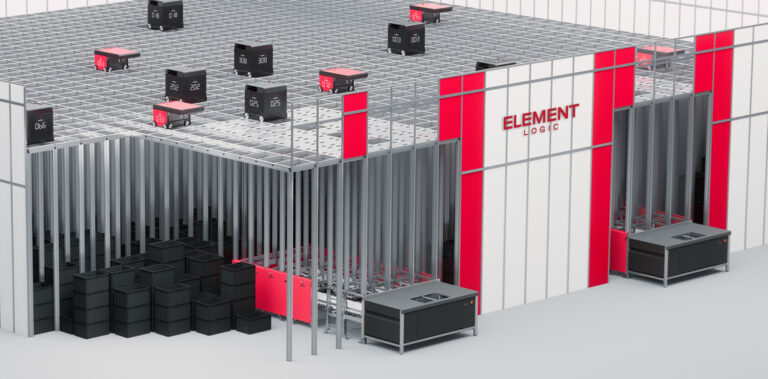

The advent of automation technologies, exemplified by systems like AutoStore, has significantly impacted warehouse compliance. AutoStore, a robotic goods-to-person system, enhances efficiency in inventory retrieval and storage. By automating these tasks, it minimizes the risk of human errors, increases accuracy in order fulfillment, and contributes to compliance with inventory control regulations. Additionally, automation reduces the physical strain on workers, promoting a safer and healthier working environment, which aligns with safety compliance standards.

Safety sensors and equipment safety technologies are instrumental in mitigating potential hazards within the warehouse. Proximity sensors and machine vision systems can detect the presence of objects or personnel in restricted areas, preventing accidents and injuries. Automated safety protocols, integrated into machinery and equipment, enhance overall safety compliance. Regular monitoring and maintenance of equipment, facilitated by technology, not only prolongs the lifespan of machinery but also ensures compliance with safety regulations and standards.

Technology has become a cornerstone in ensuring warehouse compliance. From real-time tracking and environmental monitoring to automation and safety sensors, these technological solutions not only optimize warehouse operations but also create a safer, more efficient, and compliant working environment. As industries evolve, embracing these innovations becomes imperative for maintaining a competitive edge and fostering a culture of continuous improvement in warehouse compliance.

Final thoughts on warehouse regulation

In conclusion, warehouse regulation is a critical component in ensuring the seamless and safe operation of logistics facilities. Adherence to standards set by regulatory bodies not only safeguards against legal repercussions but also promotes efficiency, worker safety, and overall industry credibility. Recognizing the transformative impact of technology in meeting these compliance standards, businesses are urged to embrace innovative solutions.

As a leading provider in warehouse automation, SDI Element Logic stands at the forefront of this technological revolution, offering cutting-edge solutions that not only enhance operational efficiency but also empower businesses to meet and exceed regulatory standards. With a commitment to excellence, SDI Element Logic invites organizations to take proactive steps toward compliance, leveraging their expertise to navigate the evolving landscape of warehouse regulation and ensure sustained success in an increasingly regulated environment.