Newsletter #71

Krish Nathan | CEO

It’s with great pleasure and excitement that I welcome you to the first Global SDI

Newsletter. For many years, SDI has released regular newsletters in various countries, which have updated readers on recent

trends, installations and the activity of our organization.

SDI has been an independent and privately operated company for over 39 years, through that time, we’ve grown and evolved by opening regional offi ces and by applying global views to solution design. We believe that having global experience of distribution operations allows us to apply the most effective and effi cient techniques to solve the varying local problems that change based on regional circumstances, culture and environment.

Recognizing that today most companies are operating, sourcing and thinking globally, SDI will now release a single global newsletter

once every two months, the SDI TODAY newsletter will cover topics from various countries allowing the reader to explore global trends and activities in one concise read.

This issue features stories from Colombia, Mexico, Peru, Chile and the USA. The objective is to broaden readers’ lens and shine a light into the process of building world-class distribution operations. In each issue, you will read an editorial from a different person in

the SDI team, in order for you to get to know our expert leaders across the globe. Our feature story is consistent with the growth we are all experiencing in E-Commerce distribution, it discusses the challenges and potential solutions for overcoming design of an E-commerce Distribution Center. We hope you enjoy this first issue and we look forward to hearing from you with ideas and any other contribution that you may like to offer.

Surviving the Growth of E-commerce

USA

It is no secret that businesses everywhere struggle with predictable and unpredictable factors. While businesses can’t control what impact the weather, for instance, will have on their deliveries, they can focus on more predictable factors in order to be better-prepared.

Fortunately, there’s a predictable factor that has become increasingly noticeable across the globe: the growth of E-Commerce sales.

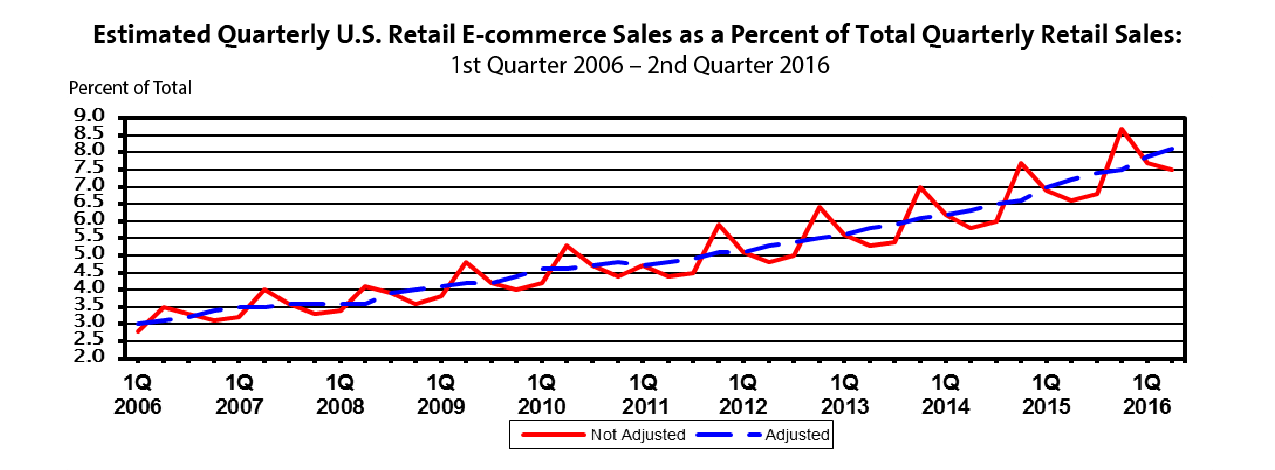

According to the U.S. Census Bureau, U.S. E-Commerce sales have been steadily increasing for the past 10 years; and according to Business Insider, Latin America is one the fastest growing regions (after Asia), with a compound annual growth rate of 17% between 2014 and 2019. This has forced businesses to adapt rapidly to clients’ E-Commerce needs in order to stay relevant and competitive.

In the DC, order patterns have changed and fulfilling those orders has become increasingly complex. A higher number of orders– with fewer items per order—is dropping, increasing the amount of time pickers spend walking around the DC, which decreases the amount of items they pick per day, while the higher number of SKUs needed in the DC demands for a bigger footprint. DCs are also experiencing a higher return rate (or sometimes even 100% return if the business is renting their product via E-Commerce), which often means DCs have to start making that process a higher priority.

DCs frequently hire more people as a “quick fix” to the new obstacles presented by E-Commerce, but that can become a costly patch for something that needs a comprehensive solution.

With the disruption of E-Commerce, SDI was posed with a new challenge: Can we come up with a new product that can cater to these new needs while having a good ROI? Through a partnership with Swiss Company, Ferag AG, SDI was able to provide an innovative solution: JOEY. JOEY (the name for a baby kangaroo) is a pouch system that reduces the number of times an item is touched, increases accuracy, and decreases the footprint, by using sophisticated algorithms that can be uniquely modified for specific DC needs and provide an infinite number of sort combinations.

This is SDI’s effort to make the newly predictable, a little easier to deal with.

SDI Announces Opening of New Office in Mexico City

MEXICO

In response to important growth of operations in Latin America, SDI recently opened a new office in Mexico City, which will better-serve current and future clients. Brazil and Mexico Country Manager, Jaime Michel, will be in charge of the office, as he has been in charge of the SDI office in Guadalajara.

In response to important growth of operations in Latin America, SDI recently opened a new office in Mexico City, which will better-serve current and future clients. Brazil and Mexico Country Manager, Jaime Michel, will be in charge of the office, as he has been in charge of the SDI office in Guadalajara.

It is important to note that the other SDI offices in Chile, Peru, Colombia and Mexico, are part of the pacific alliance, a political forum that’s seen as the engine of the productive development in the region, which will most certainly entail a lot of logistics expertise in the coming years.

PF Alimentos Prepares its DC Taking into Account New Product Lines

CHILE

Productos Fernandez S.A., cecinas PF and now PF Alimentos; three names that mark the evolution that this family Company has had in over a century in the region of Maule, Chile.

Productos Fernandez S.A., cecinas PF and now PF Alimentos; three names that mark the evolution that this family Company has had in over a century in the region of Maule, Chile.

In fact, since its beginning in 1903, when Manuel Fernandez Alvarez started to elaborate cured meats with recipes originating from Ponferrada del Bierzo, Spain, until 2010, when the Company decided to diversify into other food lines like: dairy, vegetables, pizzas, elaborated meat products, and prepared meals. The quality, responsibility and innovative capacity of PF Alimentos remain unchanged.

With that vision in mind, a couple of years ago, the Company decided to update its DC, which was located in Talca, Chile. This was with the intent of improving the efficiency of the process and to be able to better-equip themselves to confront the commercial challenges.

Industrial Division Manager, Rodrigo Aguilar, explained that the project tasked to SDI consisted of implementing a DC, which started with a consulting job focused on defining a conceptual design of the solution, in order to later follow with the engineering, and ending with the implementation of the DC in Talca, Chile.

According to Aguilar, the final phase was the installation and running the equipment and its control systems, as well as pallet storage, pallet transportation, box sorters and transporters, which entailed having a specific sequence in order to prepare mixed pallets, all of which were able to handle refrigerated and frozen products.

Why is it important for PF Alimentos to update its DC?

Mainly because the new installation allows for the expansion that our Company will require in the next ten years. There’s an increase in the quantity of clients that we need to serve, people who will be marked by the expansion of the products we will commercialize, and we intend to improve our operational conditions, we are especially interested in eliminating human intervention in the process of frozen products.

What are the main improvements achieved by building this new DC?

The main objectives that we’ve chased are to increase our storage capacity, improve our productivity in terms of processed boxes per hour, optimize our amount, decrease personnel displacement, be more precise with our inventory, and improve our service by avoiding mistakes in our product preparation.

How did the project start and continue with the SDI team?

Like all processes that involve people, we have gotten to know each other and advancing along the way, with ups and downs, which we’ve worked through and have achieved a good level of mutual knowledge, respect and accomplishment of our common goals.

What new challenges could your DC face in the future and how could SDI help?

They refer directly to the new installation. This new DC will be responding progressively to the increase in the quantity of processed orders and to the systematic demand that we have at PF Alimentos due to our operational excellence. Additionally, we are thinking about implementing the same logic we applied to this DC to the rest of our DCs across the country.

Belleza Express DC is Ready to Operate

COLOMBIA

After a meticulous process of consulting and design, Belleza Express S.A.’s new DC will start operating. This Colombian Company is a leader in health, beauty and personal care products.

SDI was in charge of this project and the objective was to design the necessary infrastructure for a DC with both, present and future needs in mind, in order to provide the client with the best practices.

Belleza Express S.A. was created in 1990 and is currently one of the biggest and most prestigious Colombian companies in this sector, they create and commercialize leading brands and have operations in more than a dozen countries: U.S.A., El Salvador, Panama, Guatemala, Peru, Ecuador, Costa Rica, Mexico, Venezuela, Chile, Guinea, Aruba, Bolivia, Nicaragua, and Dominican Republic.

Belleza Express S.A. has very complex distribution needs, which include: super markets, drug stores, specialty chain stores, health product providers, wholesale, retail, as well as other distributors; so SDI developed a DC that would allow Belleza Express to still meet its commercial and strategic objectives in the short and long term.

According to Belleza Express executives, the new DC’s design project ended last March, “This project entailed two design phases: a five-year one without any space constraints; and another one with space restrictions and a step-by-step investment over a two-to-three-year period. In both designs, SDI considered implementation of a WMS and best practices, such as the physical separation of box picking and unit picking processes, with the intent of increasing productivity and control of both procedures.”

To date, Belleza Express is finishing the implementation of SDI’s project and will proceed with the WMS, which will be the last step to go-live in the last few months of 2016.

Tgestiona’s DC Started its Operations

PERU

Tgestiona, the most important telecommunications Company and the logistics operator of Movistar Peru with a strong presence in television and across the mobile and fixed telephone grids, has improved its operations.

When it comes to mobile technology, Tgestiona is constantly faced with new challenges. Dynamic and ever-changing markets call for a permanent release of new models that include a variety of available colors among other things. These factors, along with a need for and for product availability being instantly available as well as closer to people’s place of work or home, have significantly increased the SKU count and put more pressure on a timely delivery.

According to Tgestiona DC Manager, Carlos Miranda, these market characteristics put pressure on the DC, “This made us look for new ways to operate, we obviously couldn’t sacrifice the high efficiency standards that we had in place or elevate operation costs.”

This is why Tgestiona’s team took over a year evaluating several different options to implement change and automation. The ideal solution for Tgestiona was to implement two picking zones: a pallet flow and a carton flow, which operate with a WMS that’s integrated with a Pick-to-Light.

Miranda has been very satisfied with the project because it has opened the opportunity to increase production by three-fold while keeping the same operational cost and not sacrificing anything.

“The main source of our success was in the analysis of the data of at least a year, in including the projection for growth and in evaluating the commercial changes of our clients.” Miranda added. “We were well-accompanied by SDI along the way.”

SDI is proud to have had the opportunity to work with Tgestiona, “One of the most rewarding parts for SDI, is to be able to accompany the client throughout the process of change,” Hector Mayorga, Country Manager for SDI Peru, said. “More than a provider, we are a logistics partner.”

[easy_media_download url=”https://sdi.systems/wp-content/uploads/2016/09/english-ExTERNAL-NEWSLETTER-TEMPLATE.indd_.pdf” text=”Download” color=”grey” target=”blank_”]