AutoStore Projects with SDI Element Logic - from A-Z

When investing in automation, there are a lot of things you must consider. Here is an insight on how our process as AutoStore specialists looks like.

With a wide range of expertise, user-friendly software, and more than 35 years of intralogistics experience, Element Logic will find the optimal solution for you and your future growth,” Niklas Poulsen, Sales Manager in Element Logic, explains.

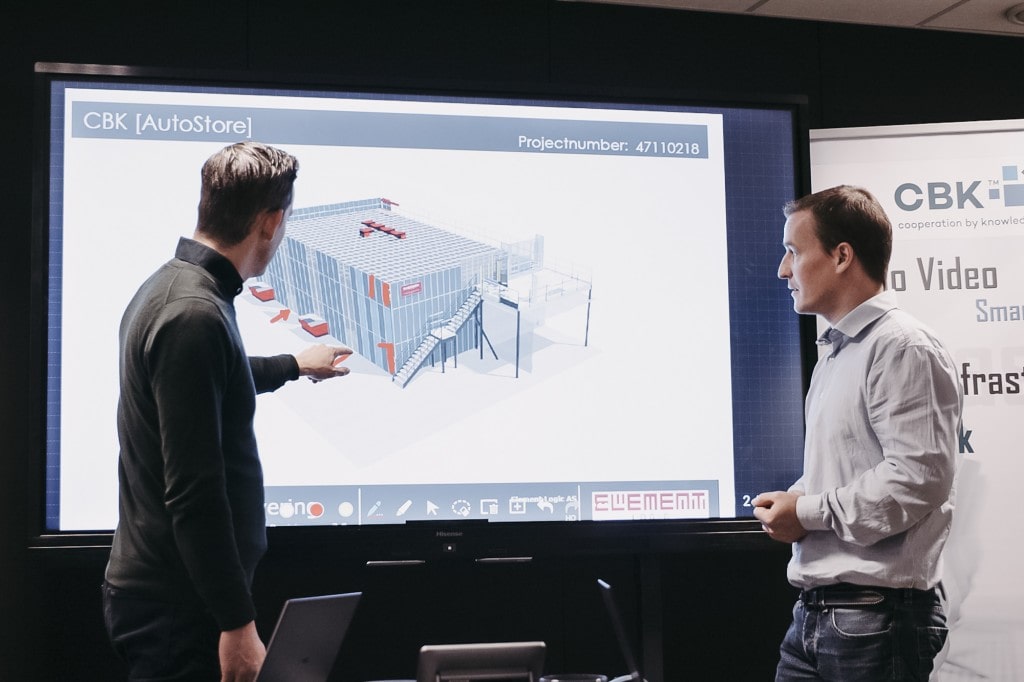

In 2020, electronics wholesaler CBK chose AutoStore by Element Logic to optimize its warehouse. See the entire process from A-Z in this video:

Establish the partnership

The first step towards automation is to contact the specialists at Element Logic. With their extensive knowledge and experience in implementing warehouse automation and AutoStore systems in warehouses, they take the lead in making ROI calculations and payback analyses to find a custom solution for your current and future needs.

The team calculates all aspects of your operations. Some calculations are straightforward, such as how many employees you will need to operate. But we also calculate how much you will save on reducing human errors in picking goods and how much customer satisfaction will increase when they experience faster and safer deliveries.

“Finally, we estimate the budget and time frame for you,” Poulsen says.

Designing a tailor-made warehouse for your specific needs

After mapping your needs and preferences, our team of system designers work closely with the sales team and Project Manager using their experience and creativity to design a customized solution for your warehouse. No solution is ever the same.

“We spend a lot of time analyzing and calculating numbers to understand your needs,” Lasse Vik, Product Manager AutoStore explains. Vik designs systems for all kinds of customers, regardless of size, shape, and challenges.

“We spend a lot of time analyzing and calculating numbers to understand your needs,” Lasse Vik, Product Manager AutoStore explains. Vik designs systems for all kinds of customers, regardless of size, shape, and challenges.

Once you sign a contract with us, we assign you a Project Manager that will work as a coordinator in all phases, and as the bridge between you and the team designing and building the solution. This way, you have one central point of contact – making it easier for you to keep track of what is happening.

“It is essential to have an open and honest dialogue about all details with the customer. This way, both sides feel confident and secure about the process,” Nils Grille, Project Manager at Element Logic, explains.

To make sure we end up with the best possible solution, the design team makes several 3D models and run simulations. These simulations will give you an idea of what you can expect from the end-result regarding capacity and efficiency.

“When we have established a draft plan based on your needs and your available space, we present this to you, and together we agree on how we execute the installation,” Grille says.

Delivery and construction

You can compare AutoStore to an advanced Lego-kit. Your Project Manager is in the lead of coordinating resources and deliveries to ensure a smooth construction phase.

“As your project manager, I make sure all the deliveries arrive at the right time. After more than 35 years in operations, Element Logic has not had any significant delays in delivering a project. Our customers highly value this accountability in a time of change,” Project Manager Grille explains.

After more than 35 years in operations, Element Logic has not had any significant delays in delivering a project. Our customers highly value this accountability in a time of change,” Project Manager Nils Grille explains.

Once the materials arrive, the construction team works on the time-consuming task of measuring out the grid and installing the first aluminum columns. Each stage of the construction is handled carefully and accurately to avoid mistakes that could affect the later stages of construction.

“When the foundation is complete, the rest of the grid is quickly built row after row by our experienced construction teams,” Grille explains.

Your entire AutoStore solution is custom-built to fit your space, needs and requests. The custom solution includes not only the grid itself but also the service mezzanine, ports, and everything else within in your unique solution. Our goal is to utilize your space in the most efficient and space-saving way.

For customers in need of a total warehouse solution, we have the competence and can support our customers with different kinds of systems and technology in addition to AutoStore.

The final step of the construction process is to place the robots on the grid.

Testing capacity and efficiency

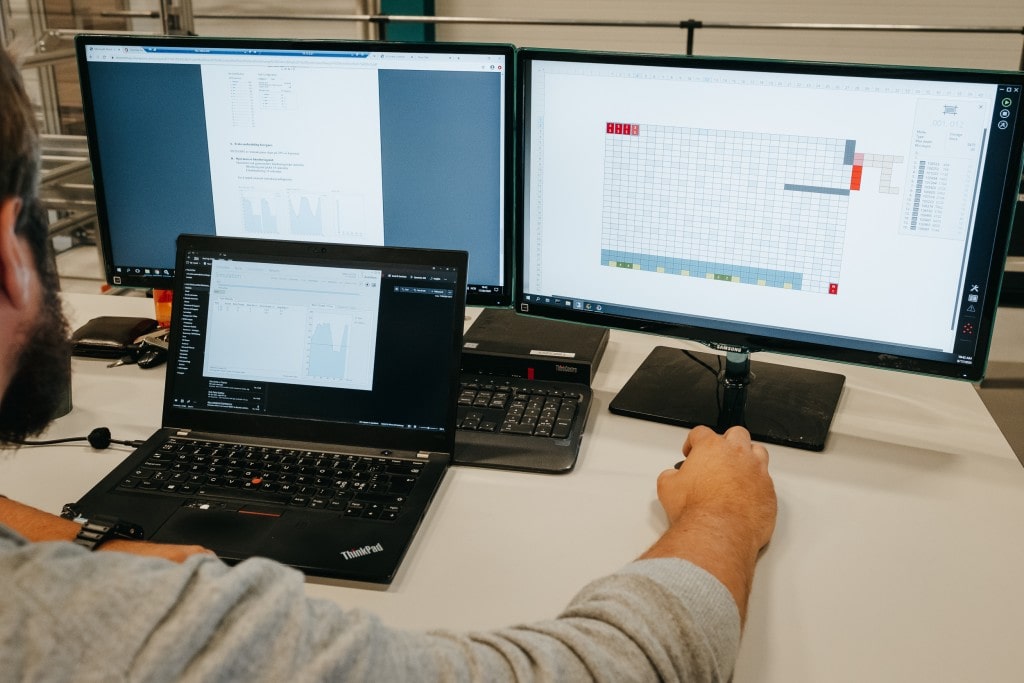

Once the robots are on top of the grid, the commissioning team executes extensive testing and simulations on scenarios. This way, you can be confident the AutoStore-system capacity matches the estimated figures from the sales process before you go live.

Our software eManager enables you to maximize efficiency and reduce operational cost. This software implements warehouse execution, management, and control systems in one optimized, user-friendly interface.

“I test the system with the customer and guide them into production. I also prepare servers for installation to make sure our software eManager is compatible with the customers’ existing systems,” Theresa Marin Tantillo, Solutions Architect at Element Logic, explains.

eManager comes with built-in operator assistance for completing AutoStore tasks, an operational dashboard, and a service portal. eManager is also used to locate and control products and inventory and can integrate with ERP/WMS, and a variety of warehouse management systems.

“I would say we are the World Champions of integrating AutoStore. eManager is the brain of AutoStore- making it efficient and enabling all components to communicate with each other for an optimized workflow,” Tantillo says.

eManager is the brain of AutoStore- making it efficient and enabling all components to communicate with each other for an optimized workflow,” Theresa Tantillo says.

Become a superuser

When we train you in your new system, we recommend a selected few to become superusers.

“To onboard you, we invite you to superuser training with practical and theoretical tasks. The focus is on operations, safety and solving different issues that could occur,” Børre Skogvold, Training Team at Element Logic, says.

The training lasts for a couple of days, and you are encouraged to work on technical and software issues with your colleagues while we are present.

Support and customer care after the installation

When the solution is ready to go live, the Element Logic support division is ready to help you in your daily operations and work with you to get the most out of your automated warehouse.

“In support, we help our customers with any issues they might face with their solution,” Wenche Schellhorn, Senior Systems Consultant at Element Logic, explains.

After completing the superuser training, you and the support division can understand each other as you can speak the same technical language and can work out the issues together.

The support team is always ready to help you with ad-hoc tasks, but they also continuously work to optimize your operations and to investigate where and how they can help you grow.

“During the construction phase, we are in the information loop and are familiar with the customer’s AutoStore-solution when they start using it and might need our help,” Arnold Nielsen, Key Account Manager at Element Logic, explains.

You can receive an SLA-report each month with detailed status on your AutoStore-solution, including downtime and completed tasks.

Seamless transition to automation

After decades of experience with AutoStore and intralogistics, we are experts in transitioning our customers from manual to automatic warehouses. Our success factor is the agility and solution-minded service team surrounding each customer – you can be confident that your solution is tailored specifically to your needs.

From the account manager, project manager, designers, constructors, commissioning team, system architects, superuser trainers and the experts in the support division, the transition to an automatic warehouse is seamless and comfortable. While simultaneously preparing your company for future growth.

The time frame from the initial meetings to an operational warehouse varies heavily. It depends on the decision-making process and your needs.

“A standard process is usually around three months from order to delivery and a few additional months of construction,” Sales Manager Niklas Poulsen states.

Secure Your Competitive Edge with AutoStore

THE WORLD’S FIRST AND LARGEST AUTOSTORE DISTRIBUTOR