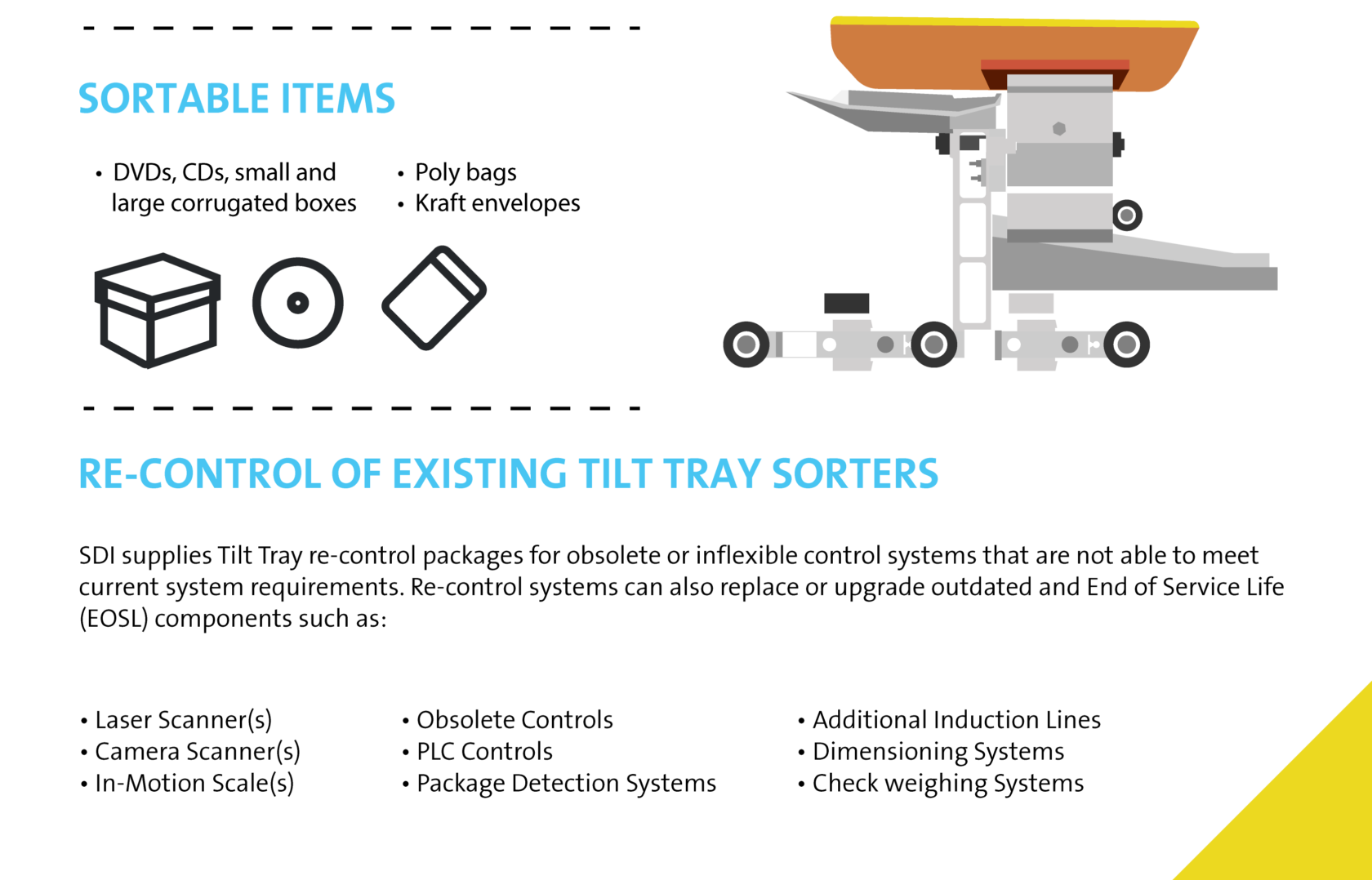

Tilt Tray Sorter

SDI’s Tilt Tray Sortation Systems are used by high volume shippers and can be designed as packing and/or shipping sorters. Either system can handle a broad range of package mix, are often employed where a large number of gates or destinations are needed and in applications with heavy volume requirements. Packages can be manually or automatically fed onto the trays and with multiple in-feed and induction areas can achieve the highest possible sortation capacities. In-motion scales can be incorporated into the automatic inducts to add check-weigh and parcel manifest capability. SDI Element Logic can design the right solution for your high speed sortation requirement.

Carriages & Trays: |

Carriages can tip to the right or left. The lubrication free carriages are locked in the upright and tipped position. |

Tilting Devices: |

All tilting devices are equipped with electric solenoids and guides to control the tipping. |

Tilt Tray Drive: |

Simple, efficient, easy to maintain tilt tray worm drives. Worm drives are gauged every 120 carriers. |

Chain: |

The aluminum chain has universal joints so the chain can bend in both horizontal and vertical planes. The chain does not require lubrication. |