As the world increasingly becomes more automated and tech-driven, warehouses look for ways to become more efficient, and still provide the same quality service. A popular option is the use of Goods to Person (GTP) robotic picking systems like AutoStore, a high-density cube storage system. In this post, we will learn about AutoStore, what we can pick with it, and the benefits compared to manual/legacy systems.

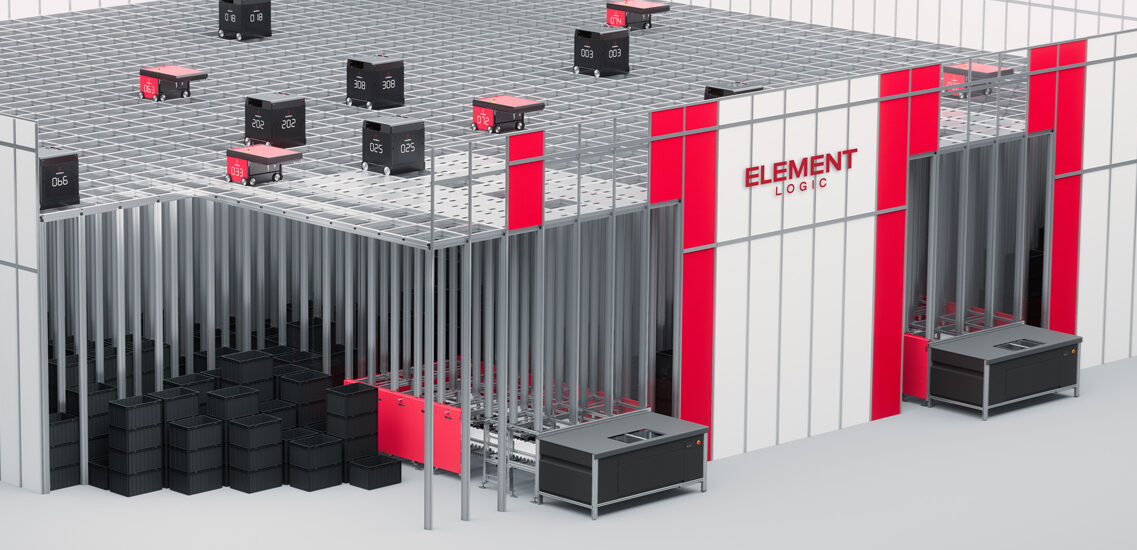

What Is AutoStore?

AutoStore is a robotic GTP system designed to streamline warehouse operations by automatically picking storage bins and delivering them directly to operators at workstations/ports. This is done through a network of robots that can quickly and accurately transport bins from one place to another, eliminating the need for manual labor, improving productivity, increasing storage density, and reducing costs.

What are the Components of Autostore?

Autostore is made up of 5 main components that work together to seamlessly automate warehouse management, including inventory storage and retrieval. Read on to learn more about each of the Autostore components and how they function together to reduce errors and increase storage capacity.

1. Grid

The grid is the framework on which the inventory bins are stacked. The grid also acts as a guide for the robots to follow. The layout of the grid can be customized to best fit the needs of your warehouse, saving up to 80% of floor space on average.

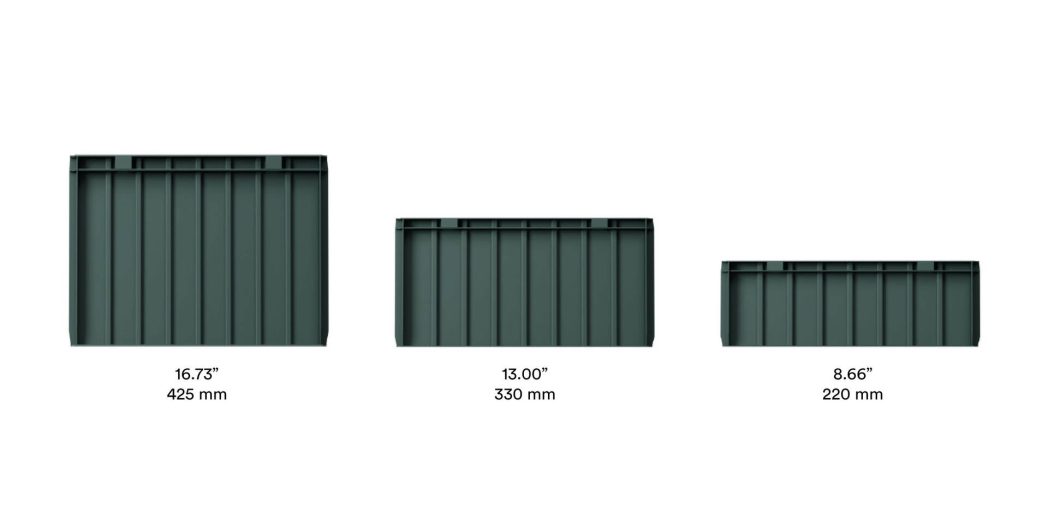

2. Bins

The bins are used to store all of the warehouse inventory, and are able to manage a variety of items. The Autostore database has total control over the contents of the bins at all times, increasing visibility into warehouse inventory.

3. Ports

The ports act as an elevator-like mechanism. They deliver the picked goods to the operator using a conveyor belt that raises and lowers to the necessary locations within the framework. Upon delivery, the warehouse worker is told which item to retrieve from the selected bin at the port.

4. Robots

The robots are essentially small carts with wheels that glide across the grid framework. They are used for picking and delivering the inventory bins using the best routes in the grid as calculated by the controller.

5. Controller

The Autostore control center is the heart of your warehouse. It is in constant control of your infrastructure and also conducts real-time logging of inventory. This helps to reduce inventory errors and ensure a strong supply chain.

Various Benefits of AutoStore

Reduced Error Rates

One of AutoStore’s standout features is its ability to significantly reduce error rates in picking and packing operations, thus enhancing order accuracy and customer satisfaction. Its advanced automation capabilities play a crucial role in reducing errors and improving order accuracy in warehouse operations.

By employing advanced robotics and software algorithms, AutoStore minimizes human intervention in the picking and packing process, which traditionally has been prone to errors due to factors such as fatigue, distractions, or simple oversight. With AutoStore, products are stored in bins within a grid-like structure, and robots navigate this grid to retrieve the necessary items for orders.

Improving Employee Efficiency

AutoStore’s implementation within warehouse environments not only enhances operational efficiency but also elevates employee satisfaction by automating repetitive tasks and enabling workers to focus on more value-added activities.

With AutoStore’s automation capabilities, many companies report on a significant reduction of menial tasks. It eliminates many routines and physically demanding tasks previously performed by warehouse employees, such as manual picking and transporting of goods. With robots handling these tasks, employees are freed from labor-intensive activities, reducing physical strain and fatigue.

Maximized Space Utilization

There are few systems in the world that can compete with AutoStore in terms of its ability to maximize space utilization within warehouse environments through the implementation of automated storage solutions. By leveraging innovative robotics and intelligent software algorithms, AutoStore optimizes storage space and layout in the following ways:

- Vertical Storage: AutoStore utilizes a grid-based storage system, where goods are stored in bins arranged in vertical stacks. This vertical storage configuration allows warehouses to make efficient use of vertical space, maximizing storage capacity without expanding the footprint of the facility. By stacking bins on top of each other, AutoStore enables warehouses to store a larger volume of inventory within the same physical area.

- Compact Design: The compact design of AutoStore’s grid layout minimizes aisle space requirements compared to traditional shelving systems. With narrow aisles between storage bins, AutoStore reduces wasted space and maximizes the use of available floor space. This compact design is particularly advantageous in warehouses with limited square footage, allowing businesses to optimize storage capacity without the need for extensive facility expansion.

- Scalability: As businesses grow and evolve, AutoStore offers scalability to accommodate increasing inventory volumes and changing storage needs. Additional storage bins and robots can be seamlessly integrated into the existing system to scale up capacity and throughput without disrupting ongoing operations. This scalability ensures that warehouses can adapt to fluctuating demand and expansion requirements over time.

Reduced Operational Costs

AutoStore’s implementation in warehouse operations brings about significant cost savings and operational efficiencies through automation, streamlining processes, and optimizing resource utilization. Below are a few ways in which AutoStore can reduce operational costs in the long term.

- Increased Productivity: Automation with AutoStore enhances overall productivity by reducing the time required to perform various warehouse tasks. Robots can operate 24/7 without the need for breaks or rest, resulting in continuous operation and faster throughput. Improved picking efficiency and order fulfillment speed further contribute to increased productivity, allowing warehouses to handle higher order volumes with the same or fewer resources.

- Optimized Space Utilization: The storage design, as we touched on above, combined with the compact layout maximizes the use of available warehouse space, eliminating wasted space typically associated with conventional shelving systems. By making efficient use of vertical space and minimizing aisle requirements, AutoStore enables businesses to store more inventory within the same footprint, thereby reducing the need for additional storage facilities or expansion projects.

- Reduced Inventory Holding Costs: With AutoStore’s dynamic storage allocation and real-time inventory monitoring capabilities, businesses can optimize inventory levels and minimize excess stock. By accurately tracking inventory levels and demand patterns, warehouses can reduce the amount of capital tied up in excess inventory, thereby lowering inventory holding costs associated with storage, depreciation, and obsolescence.

Lower Error Rates and Returns: Automation with AutoStore minimizes picking and packing errors, leading to higher order accuracy and customer satisfaction. By reducing errors in order fulfillment, businesses can mitigate the costs associated with order discrepancies, returns, and customer complaints. Additionally, the streamlined and automated processes reduce the likelihood of damaged or mishandled goods, further minimizing potential costs related to returns and replacements.

Sustainability

For companies that are looking to reduce their overall environmental impact, AutoStore is one of the greatest options available in the market. AutoStore’s automation technologies offer numerous sustainability benefits and enable environmentally friendly practices across warehouse operations and supply chain management. The top 3 benefits we see are listed:

- Energy Efficiency: AutoStore’s automated storage and retrieval system is designed with energy efficiency in mind. The robotic fleet operates on electric power, consuming less energy compared to traditional warehouse equipment such as forklifts or conveyor systems that rely on fossil fuels. Additionally, the system’s compact design and optimized routing minimize energy consumption by reducing unnecessary movements and optimizing travel paths within the warehouse.

- Long-Term Sustainability: Beyond immediate operational benefits, AutoStore supports long-term sustainability by enabling businesses to operate more efficiently and competitively in a rapidly changing global market. By adopting automation technologies that promote environmental efficiency and sustainable practices, businesses can future-proof their operations and position themselves as leaders in corporate sustainability and responsible stewardship of resources.

- Waste Reduction: Automation with AutoStore helps minimize waste in warehouse operations by improving inventory management and reducing the likelihood of overstocking or obsolete inventory. By accurately tracking inventory levels and demand patterns, businesses can optimize purchasing decisions and minimize excess stock, thereby reducing waste and the need for disposal or liquidation of unsold goods.

Resiliency

AutoStore stands out as a key solution in bolstering operational resilience and managing disruptions, particularly during unprecedented challenges such as pandemics. The core of AutoStore’s operational resilience is its reduced reliance on manual labor. AutoStore mitigates the impact of workforce shortages that may arise during pandemics due to illness, quarantine measures, or other unforeseen circumstances. With robots adeptly handling critical tasks like picking, packing, and inventory management, businesses can maintain operational continuity without compromising efficiency or productivity.

In addition to reducing dependency on human labor, AutoStore’s automation facilitates remote monitoring and management, enabling businesses to oversee warehouse operations from off-site locations. This capability proves invaluable when social distancing measures and travel restrictions may limit on-site personnel, as was displayed by the COVID pandemic.

Through remote access to real-time data and insights provided by AutoStore’s advanced software, businesses can effectively manage their operations, make informed decisions, and swiftly respond to evolving circumstances. Such agility and adaptability are essential for navigating disruptions and ensuring that operations remain resilient and responsive to changing conditions.

Aside from AutoStore’s ability to carry on remotely and reduce the spread of harmful contagions, its modular design and scalability empower businesses to quickly adapt their warehouse configurations and workflows in response to disruptions.

Whether facing supply chain disruptions, fluctuating demand, or logistical challenges, AutoStore enables warehouses to reconfigure storage layouts, adjust capacity, and optimize workflows as needed. This flexibility enhances operational resilience while also positioning businesses to thrive in the face of future uncertainties.

By harnessing the power of automation, AutoStore equips businesses with the tools and capabilities to effectively manage disruptions, maintain operational continuity, and emerge stronger from challenges like pandemics.

What Can Be Stored in an AutoStore?

The type of items that can be placed in an AutoStore depend on the size and weight of what you’re looking to store. AutoStore systems are well-suited for handling items such as:

-

- Consumer products

-

- Electronics

-

- Parts Distribution

-

- Grocery

-

- Apparel

-

- Bio-Medical

Who Benefits from Using Autostore?

While e-commerce is often the first use that comes to mind, AutoStore is also applicable, and used extensively, for retail and wholesale. Discrete order picking, batch picking, and automatic order consolidation are all possible with AutoStore– making it one of the best all-around GTP systems on the market today.

How will AutoStore benefit your operations?

AutoStore will:

-

- Reduce human error by automating many processes that would otherwise be manual labor

-

- Drastically decrease labor costs associated with warehouse operations as fewer people are required to operate the system

-

- Boost productivity in a warehouse as goods can be stored and retrieved more quickly than if they had been handled manually

By eliminating human error and reducing costs associated with warehousing activities, you can improve your bottom line and still maintain high levels of quality service for your customers. AutoStore allows you not to sacrifice quality or customer satisfaction.For more information, contact me: cory.clifford@sdi.systems or visit our website: https://sdi.systems/solutions/goods-to-person/autostore/

Conclusion

Automating your warehouse with AutoStore offers a myriad of benefits that can significantly transform your operations and drive success in today’s competitive landscape. From enhancing operational efficiency and maximizing space utilization to improving order accuracy and promoting sustainability, AutoStore’s advanced automation technologies empower businesses to streamline processes, reduce costs, and elevate overall performance.

By leveraging robotics, intelligent software algorithms, and innovative storage solutions, AutoStore optimizes warehouse management, enabling businesses to meet the demands of an ever-evolving market with agility and precision.

Ultimately, it isn’t just about optimizing productivity or cutting costs—it’s about unlocking new opportunities for growth, innovation, and customer satisfaction. By embracing AutoStore, businesses can unleash the full potential of their warehouse operations, drive sustainable growth, and achieve lasting success in today’s dynamic business environment.

For more information, contact me: cory.clifford@sdi.systems or visit our website: https://sdi.systems/solutions/goods-to-person/autostore/

Frequently Asked Questions

- FAQ 1: What is the need for automation in warehouses?

The need for automation in warehouses stems from the increasing complexity and demands of modern supply chain management. As consumer expectations continue to rise, businesses are under pressure to fulfill orders faster, more accurately, and with greater efficiency.

Automation addresses these challenges by streamlining warehouse processes, reducing manual labor, and enhancing operational agility. By automating tasks such as inventory management, picking, packing, and shipping, warehouses can significantly increase throughput while minimizing errors and reducing costs while also enabling warehouses to adapt to evolving market dynamics and fluctuations in demand more effectively.

- FAQ 2: What is the value of warehouse automation?

The value of warehouse automation lies in its ability to revolutionize operations, driving efficiency, accuracy, and scalability. By implementing automated systems like AutoStore, warehouses can optimize their processes from inventory management to order fulfillment, reducing labor costs and minimizing errors. This streamlined approach not only increases productivity but also enhances customer satisfaction through faster and more accurate order processing.

Warehouse automation provides businesses with a competitive edge in today’s dynamic marketplace. With the ability to adapt to changing demands and scale operations seamlessly, automated warehouses can meet the challenges of growth and innovation head-on. By leveraging automation technologies, businesses can unlock new opportunities for efficiency gains, cost savings, and operational excellence, ultimately driving sustainable growth and success.

- FAQ 3: How can warehouse automation benefit my business?

Warehouse automation offers numerous benefits to businesses, ranging from increased productivity and efficiency to improved customer satisfaction and cost savings. By automating tasks such as inventory management, order picking, and packing, businesses can streamline operations and optimize resource utilization. This leads to higher throughput, reduced labor costs, and minimized errors, ultimately driving profitability and competitiveness in the market.

Additionally, warehouse automation enhances agility and scalability, allowing businesses to adapt quickly to changing market conditions and customer demands. Automated systems like AutoStore enable warehouses to scale operations up or down as needed, optimize storage space, and respond rapidly to fluctuations in demand. By harnessing the power of automation, businesses can future-proof their operations, enhance operational resilience, and position themselves for long-term success in today’s fast-paced business landscape.