Article by Cory Clifford

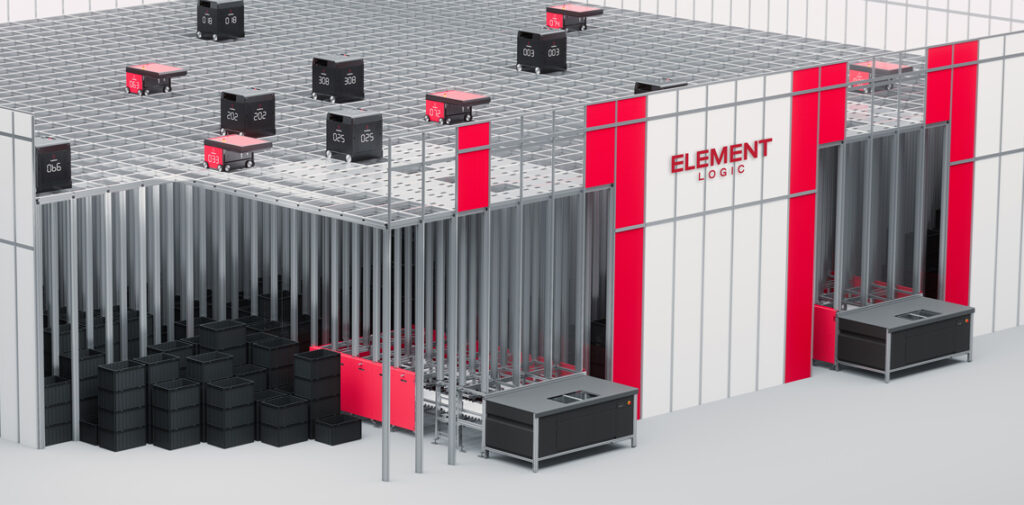

The AutoStore system is a revolutionary robotic storage and retrieval system that has transformed warehouse and distribution operations. By utilizing the latest in goods to person transportation technology, AutoStore reduces labor costs while increasing throughput and accuracy. This blog post will highlight AutoStore’s cube storage design, natural slotting concept, Pareto Principle, and how these all affect performance.

How Does AutoStore’s Cube Storage System Work?

AutoStore utilizes stackable cube storage and simplified slotting techniques to organize items within the grid. “High runners”, or the most frequently purchased items, are stored on top of the stack while the low runners, items whose sales are slower, are stored on the bottom.

This arrangement allows faster access to the higher demand items, which significantly increases system efficiency while maintaining the densest storage arrangement possible. Slotting also happens naturally as bins are taken to ports for picking and then placed back on top of the grid once the pick is complete.

The faster moving the item, the more often it will be moved to a port for picking and then placed back on the top of the storage grid. Slower moving items are not taken to ports as often, therefore they’re not placed back on the top of the grid as often as high runners. This causes low runners to sink lower in the grid. This concept naturally occurs based on the frequency of requests for various products.

What this means to our customers is you can organize and store your inventory in the most efficient way possible with no additional effort or preplanning. It also means that optimal slotting is always occurring for the system in case the relative SKU velocity of your inventory changes over the year (in case of seasonal products).

Pareto Principle and Why It’s Important

One of the ways SDI Element Logic ensures proper system design and sizing is by conducting a detailed analysis on your specific operation. Part of this analysis is a Pareto study, to understand the relative SKU velocity of your inventory. The Pareto Principle states that for many outcomes, roughly 80% of consequences come from 20% of the causes (the “vital few”).

We utilize a methodology combined with your historical data to identify the balance of your “consequences” compared to “causes” over time.. This portion of our detailed analysis process becomes a vital input as we simulate the system design to validate the proper number of robots for the system.

If you are worried that your inventory doesn’t exhibit a typical 80/20 Pareto profile, do not worry! This is very common for many AutoStore users, and a certain Pareto profile is not a prerequisite for AutoStore technology.

AutoStore even works for a totally flat Pareto (where all SKUs move at the same velocity). It is only a portion of the system design for us to validate how many robots are required for your specific operation to ensure an optimized solution.

In Summary

By utilizing AutoStore’s inherent natural slotting capabilities combined with the advanced analysis that the Pareto Principle provides, businesses can utilize this revolutionary goods-to-person picking technology for maximum efficiency throughout their entire supply chain process .

For more information, please reach out to me directly at cory.clifford@sdi.systems and visit our website here to see how SDI Element Systems can help you!