Article by Josh Beckham

Two frequent questions when considering automation systems are:

1. Is it a match for my operation?

2. Will it provide positive and measurable results?

The same questions are typically asked by anyone considering AutoStore.

Here are 5 reasons to Use AutoStore:

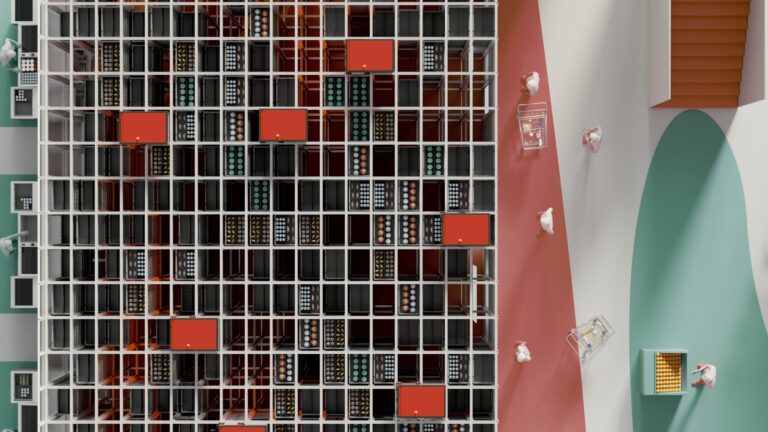

1. Density

By utilizing a cube-based design consisting of stackable bins within a grid, AutoStore can typically provide up to four times the storage capacity of conventional storage systems within the same footprint.

If your warehouse is suffering from a lack of space and you are considering expansion of your building, AutoStore may be a more cost-effective solution that can keep you in your existing space.

2. Modularity

The AutoStore grid can adapt to your DC’s footprint and can accommodate an array of obstacles such as columns or staircases.

There are many installed systems that contain features like overhangs or tunnels, to maximize space utilization and avoid the added cost of redesigning floorplans.

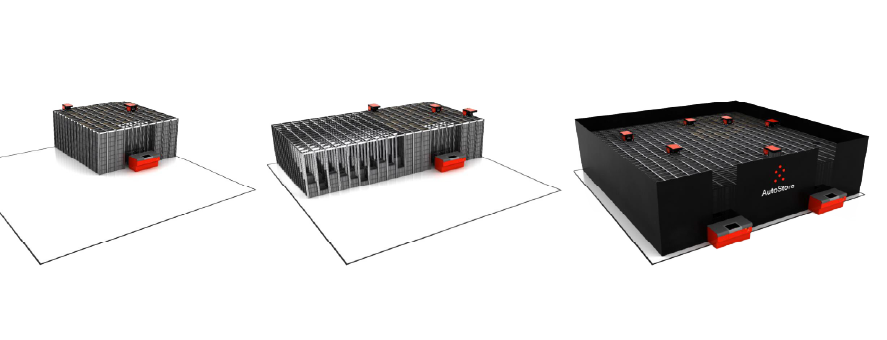

3. Scalability

The AutoStore grid is designed to easily expand as your business and needs continue to grow throughout the years without shutdown of the existing grid.

A new system can be designed with future growth in mind, leaving space for additional bins or robots to be added to an existing grid, and without increasing the overall footprint.

4. Reliability

Because all the robots within a given system work independently from one another, there is no single point of failure. On average, AutoStore systems globally have an average up-time availability of 99.7%

The system can even support 24/7 operations and the robots do not require warehouse lights to operate.

5. Productivity

The overall productivity of an automated system is often a crucial factor when deciding on a technology. Compared to conventional pick and replenishment tasks, the AutoStore system can not only perform both simultaneously, if desired, but can also consolidate entire orders at a single port. Reducing travel time to manually process orders and complete putaway tasks significantly increases throughput and maximizes efficiency.

By minimizing human dependency, fulfillment accuracy errors can be avoided and ensure order accuracy in every instance.

If you’d like to discover more benefits of using AutoStore for your warehouse operations, read more about it here.

What’s Next?

Understanding what makes the AutoStore system a revolutionary solution is just the first step into starting the implementation process. As part of making sure that an AutoStore solution is well-suited for your business, SDI Element Logic does an in-depth quantitative data analysis. As the world’s first and largest AutoStore integrator, we have the knowledge and expertise to guide you through the execution process and provide the greatest support every step of the way.If you are interested in learning more about AutoStore and how we can optimize your warehouse performance, contact me: josh.beckham@sdi.systems or visit our website https://sdi.systems/solutions/goods-to-person/autostore/.